Looking to elevate motion control and precision in your steel or metal processing operation? At TR, we specialize in cutting-edge motion feedback solutions for the steel industry, designed to thrive in the harshest industrial environments. Our innovative range of encoders and protective housings is engineered to deliver accuracy, durability, and seamless integration, ensuring your production processes run smoothly with minimal downtime.

Here’s a closer look at some of our industry-leading motion feedback systems:

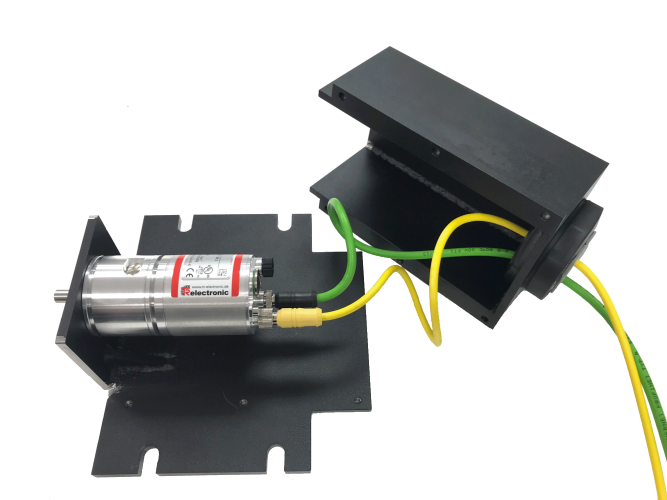

DAG Heavy-Duty Housing: Built for Maximum Reliability

The DAG Heavy-Duty Housing is a rugged solution tailored for the high-stress environment of steel mills. It supports extreme shaft loading, offering the resilience and strength needed in demanding applications.

-

Houses one or two encoders for redundant operation

-

Minimizes downtime through backup capability

-

Ideal for steel industry operations requiring precision positioning and continuous performance

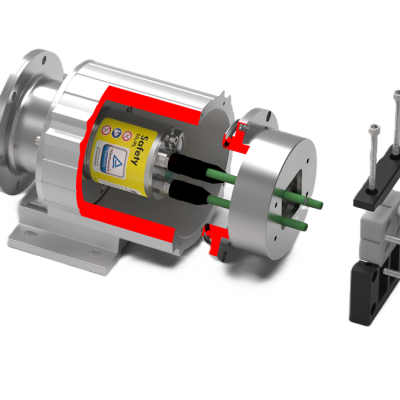

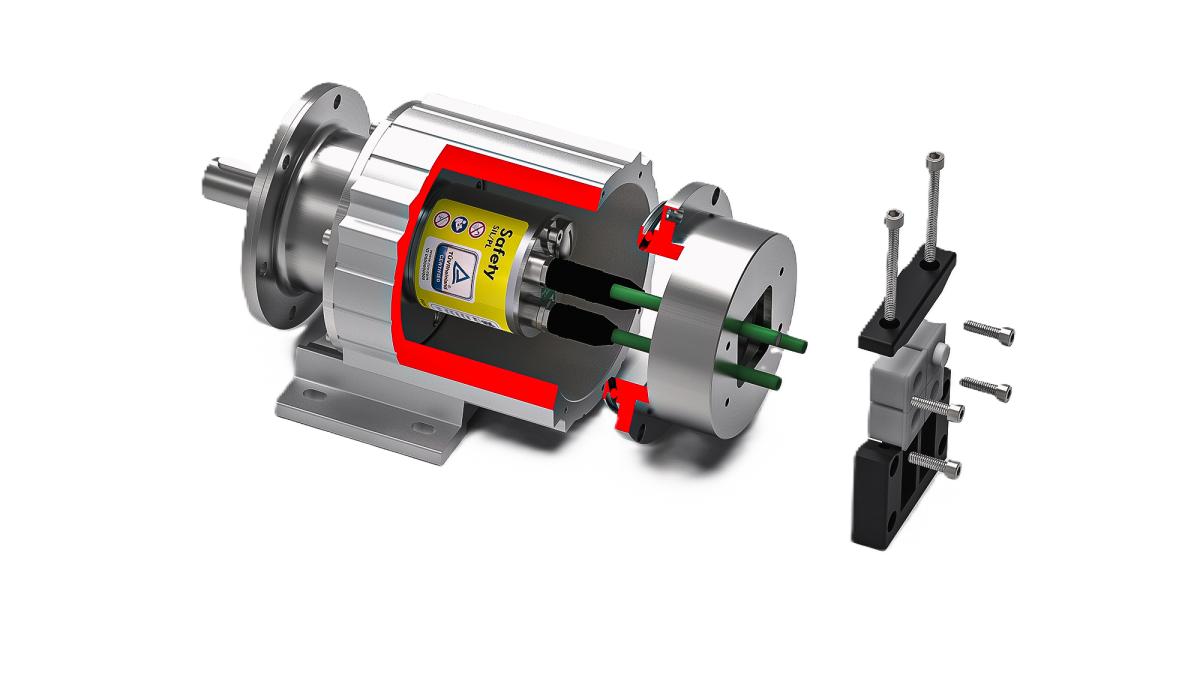

KCBM Housing: Drop-in Replacement for Carlen CC3820R Resolvers:

The KCBM Housing is the perfect bolt-on solution when transitioning from outdated resolver technology. Designed to replace the Carlen CC3820R without any drilling or rework, it significantly reduces installation time and costs.

-

Simplifies the upgrade to modern absolute encoders

-

Minimizes modification with its plug-and-play compatibility

-

Optimized for use in legacy steel mill systems

Learn more about DAG/KCBM Housing

CEV_84 Stainless Steel Encoder: Tough & Connected:

The CEV_84 is a robust stainless steel encoder engineered for harsh industrial environments. With direct interface, fieldbus, and Industrial Ethernet connectivity, it ensures seamless communication in demanding applications.

-

Corrosion-resistant stainless steel body

-

Suited for extreme heat, dust, and vibration

-

Ideal for integration in modern steel processing lines

C_V115: Proven Housing for Harsh Conditions:

The C_V115 series features a tried-and-tested design that delivers durable encoder protection in rough environments. Its massive bearing units absorb high shaft forces, protecting sensitive internal components.

-

Mounts via solid flange or foot for versatile applications

-

Withstands heavy impacts and collisions

-

Perfect for use in steel mills with high mechanical loads

Learn more about Heavy Duty Absolute Encoders

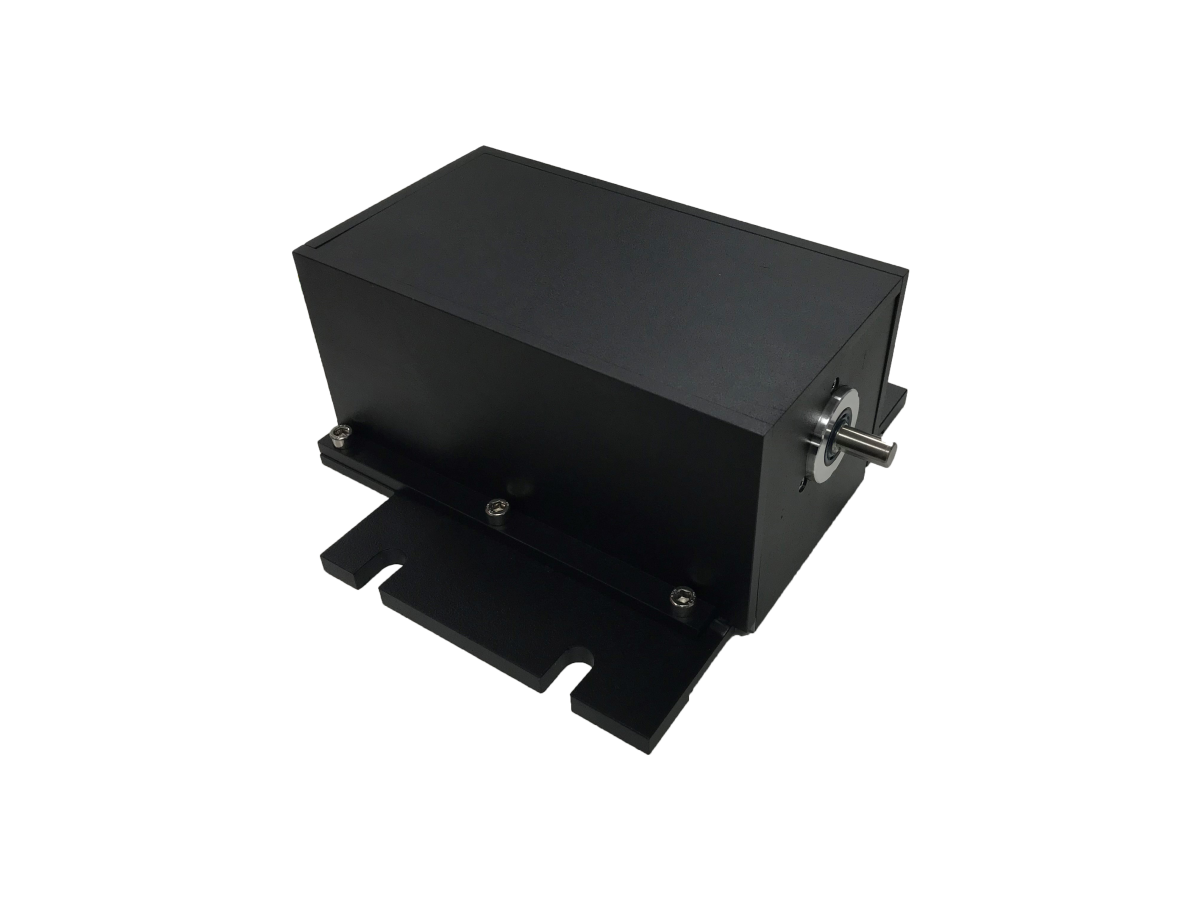

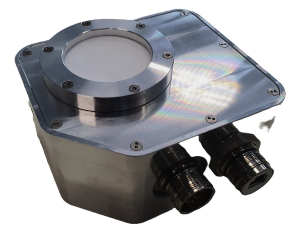

New C_1152 Protective Housing: Reinvented for Extreme Duty

The latest C_1152 housing offers enhanced mechanical strength with a reinforced mounting flange and a thick aluminum casing. It provides superior impact resistance and advanced protection for encoders in dusty and rugged settings.

-

20 mm wall thickness for added protection

-

Innovative connection bell for easy M12 connector access

-

Compatible with 582 series encoders

Linear Encoders: Precision Motion Sensing Over Long Distances:

Our linear encoders are ideal for measuring linear motion with minimal wear. Whether you're dealing with machine tools or large-scale automation, these encoders offer long-distance measurement and high accuracy.

-

Measures up to 20 meters with contactless encoders

-

Laser systems allow up to 240 meters of range.

-

Enhances precise control and automation in steel processing

Mecorad Radar Sensor: Smart Measurement for Hot Metal Forming

The Mecorad Radar Sensor stands as the pinnacle of smart, non-contact measurement solutions for hot metal forming. Whether you’re working with steel or non-ferrous metals, Mecorad delivers real-time, in-line measurement and process optimization across both upstream and downstream stages.

-

Utilizes advanced radar technology for precision under extreme conditions

-

Enhances control and throughput during hot forming operations

-

Enables smart process automation and real-time quality assurance in steel and metal industries

Why TR Motion Feedback Solutions?

TR is a trusted name in industrial motion control with a focus on delivering durable, high-performance encoder systems for the steel and metal industries. Our solutions are built to withstand heat, impact, dust, and vibration — the everyday challenges of steel production.

🔩 Improve positioning accuracy

🧰 Reduce maintenance needs

⚙️ Boost operational uptime

📅 Looking Forward to Seeing Our Solutions in Action?

Want to experience our technology firsthand? Don’t miss the chance to explore TR’s cutting-edge solutions at industry-leading exhibitions and events around the globe.

👉 Check out our events schedule now!

Come meet our experts, see live demonstrations, and discover how TR’s motion feedback solutions can transform your steel manufacturing process.